SPG Dry Cooling Products |

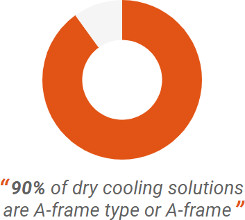

Air Cooled CondensersAir Cooled Condensers directly condense exhaust steam from the steam turbine without water consumption. They are frequently used in electrical power plants and waste to energy plants of all sizes. Features An Air Cooled Condenser (ACC) is a direct dry cooling system where the steam is condensed inside air-cooled finned tubes. Since there is no intermediate surface condenser like Indirect Dry Cooling, the overall performance is better. The SPG Dry Cooling Air Cooled Condenser features long-term mechanical and thermal integrity, excellent corrosion and freeze resistance, low fan power consumption, reliable operation and low maintenance. An Air Cooled Condenser (ACC) is made of modules arranged in parallel rows. Each module contains a number of fin tube bundles. An axial flow, forced-draft fan located in each module forces the cooling air across the heat exchange area of the fin tubes. The typical scope for an ACC installation includes the supporting structure, the steam ducting from the steam turbine interface, auxiliaries such as the condensate and drain pumps, condensate and duct drain tanks, the air evacuation units and related piping works and instrumentation. Benefits The major benefits of Dry Cooling are:

|

|

|

ModuleAir® Air Cooled CondensersAir Cooled Condensers directly condense exhaust steam from the steam turbine without water consumption. They are frequently used in electrical power plants and waste to energy plants of all sizes. ModuleAir® Air Cooled Condensers Benefits

Features ModuleAir® is a modular version of the conventional A-frame SRC® Air Cooled Condenser design featuring factory assembled structural components, duct and modular heat exchanger bundles. With construction savings of up to 25%, construction time can be reduced by several months for large power plants. ModuleAir®can also increase power production at low ambient air temperatures.

|

|

|

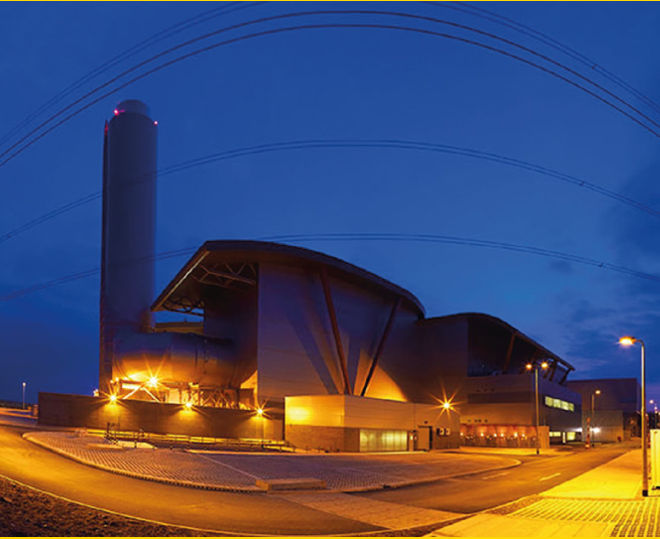

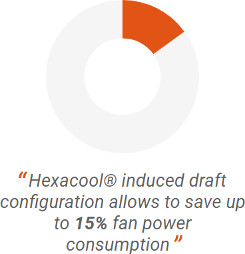

Hexacool® Air Cooled CondensersHexacool® is an air cooled condenser (ACC), well suited for use in waste to energy, biomass and small size electrical power plants and industrial co-generation. For small power and industrial applications, SPG Dry Cooling, Inc. specifically developed its Hexacool® ACC with the goal of offering a standard modular system that would be low in cost, easy to erect and robust in performance. Details and options The HEXACOOL® Air Cooled Condenser offers the following benefits:

Features A Revolution in Air Cooled Condensers. |

|

|

BoxAir ACC®BoxAir ACC® is an innovative Induced Draft Air Cooled Condenser (ACC), suitable for all power plants ranging from 1 to 30 MWe. BoxAir ACC® is an ACC type, integrating standard boxes that are easy to erect. The extended standardization, also enables to insure a very short delivery schedule, and a high reliability level. BoxAir ACC®‘s typical applications are waste incineration plants, biomass, solar and geothermal power plants, or capacity increase of any existing power plant. Features BoxAir ACC® is an Induced Draft Air Cooled Condenser (ACC), made of several standard boxes in- stalled side by side. The Single-Row Condenser tubes (SRC®) are arranged in two deltas inside the BoxAir ACC® box. The deltas are delivered with welded-on steam manifold and condensate collection headers. The air is drawn across the finned tubes thanks to two axial flow fans located on top of the BoxAir ACC® box. This ACC concept drastically reduces site welding and presents a much higher degree of preassembly, compared to a standard A-frame design. The construction duration is therefore minimized. Benefits The major benefits of BoxAir ACC® are:

|

|

|

W-Style ACC®Our W-Style ACC® is an innovative induced draft Air Cooled Condenser (ACC) directly condensing the steam turbine exhaust flow. The condensate returns to the boiler without water loss as in traditional ACC. With its unique “W” heat exchanger arrangement, the amount of structural steel and overall ACC height are dramatically reduced as compared to traditional forced draft arrangements. With its reduced finned tube length as compared to other ACCs, reduced ACC back pressure can be achieved and flow accelerated corrosion risk notably reduced. Features The W-Style ACC® module utilizes our proven Single-Row Condenser (SRC®) finned tubes. The heat exchangers are arranged in a “W” orientation. Two large steam manifolds at the bottom distribute the steam to the heat exchangers. To promote effective non-condensable gas extraction, the heat exchanger arrangement includes primary, secondary and tertiary tubes. Mounted above the heat exchangers are the induced draft axial fans, gearboxes and motors. The “W” arrangement provides central support for the fan bridge mitigating vibration. Benefits The major benefits of W-Style ACC® are:

|

|

|

Indirect Dry Cooling (IDCT)About IDCT Indirect Dry Cooling (IDCT) systems have been used for over 50 years for various applications in the power industry. Active for more than three decades in the indirect dry cooling market, SPG Dry Cooling has supplied the largest indirect system presently in operation in the world. IDCT Indirect dry condensing system couples an indirect dry cooling tower (IDCT) with a steam surface or jet condenser and is suited for large capacity condensing units. Its tall concrete or steel shell eliminates hot air recirculation. Auxiliary is power minimized as is the number of mechanical components. This translates into reduced maintenance and high availability. MIDCT Mechanical Indirect Dry Cooling Tower (MIDCT) is particular type of IDCT where the cooling air flow is not the results of the natural draft from a tall concrete or steel tower but is fed from fans driven by electrical motors. MIDCT are particularly suitable for the Wet to Dry conversion or cooling capacity extension of existing IDCT. Details The IDCT is a dry cooling system whose major benefits are:

|

|

|

Air Cooled Heat Exchangers (ACHE)Air Cooled Heat Exchangers (ACHE) are a family of custom designed heavy duty fin tube heat exchangers which allow the direct cooling by air of various process mediums. ACHEs are used for many Industrial Applications, such as Power, Chemical, ORC Plant, Oil & Gas, Steel Industry and many other Applications. |

|

|

Air Cooled Heat Exchangers

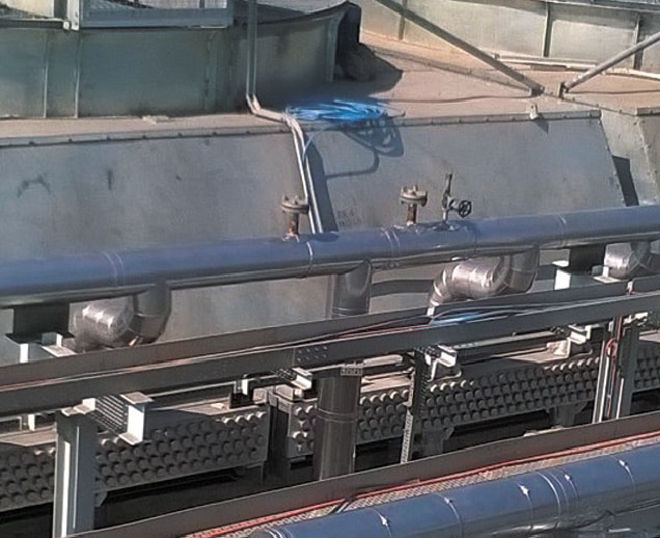

ACHE Technology The Finned Tubes are the core Technology of Air Cooled Exchangers. Wide range of Finned Tubes available including round tubes with L-Fins, Extruded Fins, Multi Channel tubes (MCT), Round Aluminum Fin Tube (RAFT,… Various Header Configurations and materials. Features An ACHE installation includes the finned tube heat exchanger header, steel support structure, fan drive equipment, including axial fans, V-belt drivers, bearing shafts and electric motors. A wide variety of core tube materials and header configurations are available to meet an extensive application scope in terms of maximum working temperature, corrosion resistance and mechanical properties. |

|