Water plantsSeawater Desalination Plants |

|

|

Known for delivering advanced and reliable desalination plants, Doosan is one of the few companies in the world that offers proprietary technologies for all three main desalination processes: Multi-Stage Flash (MSF), Multi-Effect Distillation (MED), and Reverse Osmosis (RO). |

Related Products |

MULTI-STAGE FLASH (MSF) With the MSF (Multi-Stage Flash) method, sea water flows through a multi-level heat exchange system, is heated with steam from the power generating plant until evaporation, and is then condensed on the outside of pipes through which cold seawater flows. The MSF method generates fresh water from seawater using flashing which is a phenomenon of instantaneously discharging water vapor. MSF is a facility designed to use energy more effectively by continuously generating flashing of seawater at low steam pressure from each stage without the addition of heat source. |

MULTI-EFFECT DISTILLATION (MED) MED (Multi-Effect Distillation) is similar to MSF, but only makes use of devices called Effect instead of “Stage” from MSF. The MED method has the advantage of reducing energy consumption if applied with dump heat, and is mostly used for medium-capacity desalination plants. Its principle is to spray seawater on the outside of metal tubes to condense the vapor flowing inside. The seawater outside the tube boils to generate steam which flows into the tubes to condense in the next cycle. The process is then repeated. Since the outside of the tubes is maintained in a vacuum, the seawater boils even when it is sprayed at a low temperature. The big difference from MSF is that it is relatively smaller in size as it is operated at low temperatures (60 ~ 70 ºC) but is more efficient and consumes less electricity per unit production. |

REVERSE OSMOSIS (RO) As the name suggests, pressure is applied to seawater in order to separate substances like water and salt and thereby produce fresh water. Its relatively easy operation and low energy consumption make it ideal for all capacities - small, medium and large plants. The first commercial operation of RO dates back to the 1970s. Compared to MSF and MED, RO is a relatively recent technology. RO uses semi-permeating membrane to separate water from the solute in the seawater. In RO, most of the energy is needed to pressurize the feed water. The seawater desalination by RO system consists of pretreatment system, high pressure pump and RO membrane. The auxiliary units include water intake and effluent systems and power reception and transmission systems. |

Water Treatment Plant |

|

|

Doosan Heavy Industries & Construction has outstanding capabilities in cutting-edge membrane technologies such as Membrane Bio Reactor (MBR) and Reverse Osmosis (RO), as well as in recycling through sludge retreatment and Zero Liquid Discharge (ZLD). This enables us to deliver sustainable and optimized total water solutions for all segments of water business. |

Related Products |

DRINKING WATER SYSTEMS Doosan Heavy Industries & Construction provides specialized water treatment systems that meet the strict drinking water requirements in order to cater to diverse customer needs for safe water. |

INDUSTRIAL WATER SOLUTIONS Doosan Heavy Industries & Construction provides water solutions for the production of top-quality pure and ultrapure water. The company’s high-quality, customized water production systems are used in power plants and other industries, such as oil refining and petrochemical, semiconductor, beverage and pharmaceutical industries. |

SEWAGE TREATMENT AND REUSE As a leader in sewage treatment, Doosan Heavy Industries & Construction provides customized solutions, ranging from simple primary treatment systems to advanced systems that use the membrane process, thereby enabling customers to produce water of the desired quality. |

WASTEWATER SOLUTIONS Doosan Heavy Industries & Construction provides solutions for stable and effective pollutant removal and wastewater recycling for all types of industrial wastewater including recalcitrant wastewater. Many customers benefit from these solutions with regard to environmental issues, operating costs and waste disposal. |

SLUDGE TREATMENT AND RESOURCE RECYCLING Doosan Heavy Industries & Construction takes the initiative in mitigating environmental problems and improving economic efficiency by providing environment-friendly recycling systems that facilitate the reduction and stabilization of sludge as well as utilize gas generated from power and industrial wastewater treatment facilities. |

Water Treatment Equipment |

|

|

Doosan Heavy Industries & Construction greatly satisfies customers in various industrial sectors around the world by supplying them with differentiated, high-quality and high-efficiency products applicable to a wide range of water treatment areas. |

Related Products |

ENERGY-SAVING MEMBRANE BIOREACTOR (LENA MBR) LENA MBR technology offers advances in energy efficiency and membrane performance utilizing Inertia Force on Membrane Fibers by Reciprocating Motion as a Solution to Energy Intensive Air Scouring. |

ZLD (ZERO LIQUID DISCHARGE) Doosan Heavy Industries & Construction provides highly efficient Zero Liquid Discharge (ZLD) facilities that use membrane and evaporation and concentration technologies to enable customers to minimize the waste of water with zero discharge of wastewater and build environment-friendly plants. |

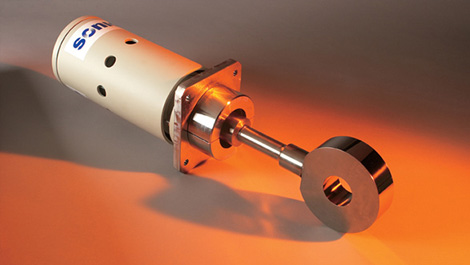

ULTRASONIC SOLUBILIZATION DEVICE (SONIX™) sonix™ uses ultrasound at 20kHz to enhance the solubility of organic sludge or other organic waste using cavitations. This not only maximizes sludge reduction in aerobic and anaerobic digestion ponds, but it also reduces sludge bulking and foam formation during wastewater treatment, while enhancing the removal of nitrogen and phosphorous when used with the Biological Nutrient Removal (BNR) process. |

DAF (DISSOLVED AIR FLOTATION) Doosan Heavy Industries & Construction owns Dissolved Air Flotation (DAF) process applicable to many aspects of water treatment. It also offers accumulated expertise and high-quality products that are highly received from its customers worldwide. |