SC or CC Power Plants based in GT |

DOOSAN HEAVY INDUSTRIES

|

|

Related Products |

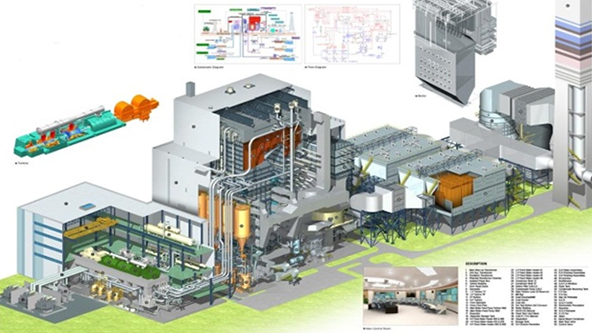

COAL-FIRED THERMAL PLANT |

COMBINED CYCLE POWER PLANTCOMBINED CYCLE POWER PLANT |

ULTRA SUPER CRITICAL PULVERIZED COAL THERMAL POWER PLANT

|

PURE OXYGEN COMBUSTION TECHNOLOGY

|

INTEGRATED GASIFICATION COMBINED CYCLE |

PROENERGY |

Field Services

ProEnergy's Field Services Division prides itself on providing the highest quality workmanship, on time and cost-effectively, while exceeding environmental responsibilities. Whether it is turnkey project execution or seamlessly supplementing your team, we deliver efficient productivity through proactive planning, project management, quality assurance and attention to safety. From pre-outage planning and project execution to post-outage reporting, we make optimal use of limited downtime and properly maintain equipment for effective plant operation. ProEnergy's Field Services include: |

Operations and Maintenance Services

ProEnergy Services O&M philosophy focuses on safely maximizing plant equipment reliability, availability and performance. This is accomplished while maintaining a balanced, cost-effective approach of O&M expenses over an asset's life in which to protect its long-term value. We are flexible enough to tailor fit a specific O&M program with proven policies, procedures and processes that will ensure your project’s success. ProEnergy's O&M Services always maintains the highest safety standards while exceeding environmental requirements. Our team manages their jobs from a customer-satisfaction approach, and brings to the project the training and experience necessary to achieve the highest results. We recognize that providing consistent, effective and comprehensive support to a plant staff is paramount. ProEnergy's Operations and Maintenance Services include: |

Professional Services

ProEnergy’s Professional Services Group provides technical specialists and project management personnel internally and to our industry clients, through all phases of a project, including development, engineering, construction, commissioning and ongoing operations and maintenance. |

Technical Services

Our Technical Services team provides optimum project support through proven processes in testing, training, procedure documentation and qualification. Our site-specific training programs are renowned in the industry and focus on teaching your staff the principles of operation and maintenance, as well as efficiency maximization for your plant. |

Process Services

Through ProEnergy's Process Services Division, experienced teams of technical specialists and craftsmen help industrial customers make the changes necessary to improve plant processes, productivity and efficiency. |

Fabrication Services

ProEnergy's Fabrication Services group executes projects for industrial customers around the world, as well as close to home. ProEnergy manufactures, retrofits, installs and tests a variety of steel products used in construction, operation and maintenance for industrial customers in manufacturing, food processing, power, fuel refining, material handling, water treatment, and chemical/petroleum refining processes. |

Energy Parts Solutions

Energy Parts Solutions supplies the highest quality parts and equipment to the energy industry at competitive prices. To help power providers continue operations and repair outages with minimal downtime, EPS keeps a vast inventory of replacement parts for all major industrial gas turbine technologies in stock at all times. |

EPC Services

ProEnergy's professional team of EPC specialists provide turnkey engineering, design, procurement, and construction management, as well as start-up, commissioning and testing for aeroderivative and frame units. |